|

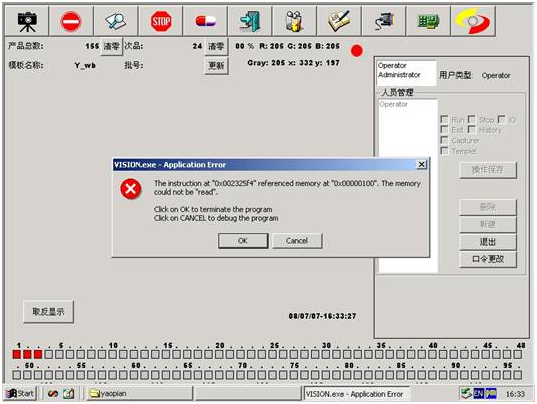

System failure processing |

||||||||||||||

|

|

The packing box for computer case and computer are specially designed

which has the quakeproof function, it can withstand the normal hit during

transportation. If the user needs to transport the main computer, first please properly protect all instrumentation equipments; only after taking following steps can the user carry on the transportation.

1.Well preserve all useful documents.

3.Separate the host computer with

outside supports, dismantle the electrical cable, and tear off the electrical

wire and other external instruments installed on the host computer case. |

|

Do not dismantle any parts or components when the power is on. Pay attention to static when maintenance!

1.What is static?

moving of electrical charge from one object surface to another. All

electrical components have the risk

can catch the static effect with above 3000V, however, lots of electrical

components Get rid of materials which produce static, such as carpet, plastic. |

|

1.No

24V DC, check 24V power supply.

2.Wrong rejection after a period of time use.

1.Check

the format-setting area (that is: x0, y0, x1, y1). 3.Detect the foreign matters in the inspecting area, whether there is non-tablet/capsule matter with the gray level between 0-1V.

4.No image in inspecting display area. 5.The image is not in the center of the inspection interface.

Start

inspection system to enter into inspection interface, click“real-time show”

icon. 5.Regulate the lens to clear the vision.

6.Inspection leakage.

③It may be caused by manual action.

correct operation, to eliminate mechanical breakdown, and to wipe the lens

and light source regularly.

compare the number of blisters rejected ahead of time or lag behind, 11.No response on inspection interface.

Maybe click many times on RUN for starting on Inspection interface.The solution: click on RUN only once

when coming t

12.It was forbidden to connect or dismantle components when the power is on. |

Copyright Copyright (C) 2015-2020